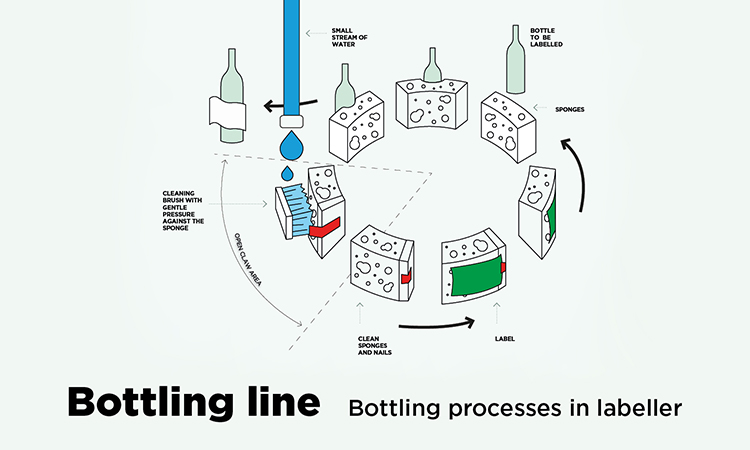

Label Drop

THE PROBLEM

Generally this problem is associated with a low surface tension in the bottle.

THE ORIGIN OF THE PROBLEM

Glass bottles in untreated virgin state generate friction with each other during transport (glass factory-bottling site-market), resulting in a scratched appearance of the bottle not accepted by the market.

The glass manufacturer resolves it with the application of substances with sliding effect, reducing the friction coefficient between bottles which in turn decreases the surface tension of the glass.

In cases where such treatment is excessive, bottle adhesion is so difficult.

BOTTLE SURFACE TENSION

High surface tensions (> 42 dynes-cm): Good adhesion

Low surface tensions (<38 dynes-cm): Precarious adhesion (possible label drop)

Virgin glass bottle: 300 dynes-cm

Glass bottle with treatment :> 42 dynes-cm

THE PROBLEM SOLUTION

The adhesive to be used must always have a surface tension lower than the bottle.

When collars and labels fall, the Surface Tension of the bottle should be studied and the adhesive adapted to that batch of bottles.

Note: bellow conditions can aggravate the problem, but in essentially the most common cause is the one noted above

Bottle temperature

Glue temperature

Paper type used by the printer